The UltraLoft Nonwoven Line consists of three different aspects of the production process including fiber preparation, web forming and finish system.

The UltraLoft Nonwoven Line can transform your plant into a highly efficient and higher profit operation.

The line consists of everything you need including:

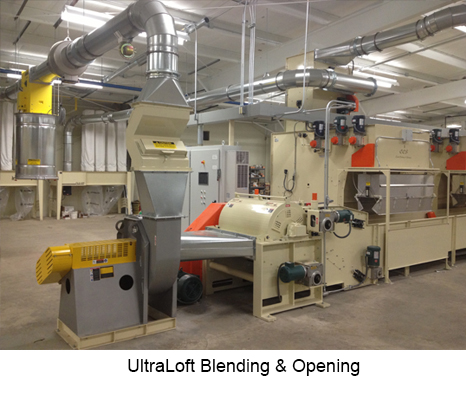

The UltraLoft fiber Blending and Opening Line includes multiple Feed Hoppers that begin to opening the fiber and weigh the individual fibers to get an accurate blend percentage. Once the different fiber are weighed and layered in the Blend Conveyor, the fibers are conveyed into the Fine Opener. The UltraLoft Fine Opener will further open the fiber and properly blend the different fibers together.

A typical CCS Thermal Bond Nonwoven production line would include an UltraLoft Pre Opening System for the low temperature fiber and a UltraLoft Recycle System to process any edge trim or waste material that needs to be blended back into the finish product.

Once blended, a typical MaxLoft pneumatic conveying or feed system is used to transport the fiber from the blend line to the Card machine. The feed system could include features such as inline hump magnet, active metal extractor, differential pressure switch, site tube, material fan and duct work. A negative pressure system is used to reduce the amount of static and airborne fiber or dust.

The UltraLoft Reserve Feed Hopper includes a photo electric sensor that controls the amount of fiber in the Feed. A second photo electric sensor operates a spiked lift apron in the Reserve Feed Hopper which maintains the level of fiber in the Shaker Chute. The purpose of the UltraLoft Shaker Chute is to create a uniform fiber batt and feed the fiber batt to the Card Machine.

The UltraLoft Card machine will process most fibers at a high rate while producing a uniform web. The Carding machine includes features such as VFD drives, metal detection, speed sensor to protect from overloading, lexan covers, platform, safety enclosure with motion detection, randomizer or high speed comb and air assist take off.

The UltraLoft Card machine includes an auto doffed and self threading feature, this will allow the operator initiate the fiber then monitor the machine while the system begins running product automatically. The Carded web will enter the UltraLoft Cross Lapper, the Lapper will layer the fiber to the correct product width, thickness and weight. The Lapper includes a hanging floor apron; the height of the apron can be adjusted depending on the product thickness. All the product specs and machine data is displayed on the touch screen.

The Carded and Cross Lapped batt enters the Thermal Bonding Oven and Cooling Zone for the final process. The oven conveyor speed, temperature and fan speeds are all controlled and saved as part of the product recipe. The Bonding Oven brings the process air to the desired temperature and directs the hot air through the product. Once the air passes through the product the air is reheated and returns for another pass. Once the product exits the heat zone it enters the Cooling Zone. Here cool air is passes though the product to stabilize the structure.

Once the product is bonded and cooled it will enter the UltraPro Slitter to be cut to width, This can be done with either compression or high speed blades. The positioning of the blades and cut length can be saved as the product recipe. The UltraLoft Rotary Cut Off machine is used to cut the product to length. The UltraLoft Wind Up is used to wind the finish product on a center mandrel.

A typical UltraLoft PLC electrical control system includes recipe management which allows the operator to change products with a touch of the screen; the production lines can be run from a smart phone or tablet. The MaxLoft control system includes features such as colored touch screen monitor, air conditioning, lighting, password protection, self diagnostics, CAD graphics, active weighting system, trending, motion detection, flash drive storage, battery backup and VPN access for remote support.